Critical Power in Pharmaceutical and Life Sciences Manufacturing

Recently, you may have heard (or read) a lot about secure power and electric reliability. And, if you’re like most organizations, that’s probably made you rethink your critical infrastructure strategy.

Extreme weather events that were thought to be once-in-a-generation are becoming all too common, and with them come many challenges that have made many look at their operations differently. As a result, we’re hearing a common theme: Reliable power is essential for productivity and revenue.

Keeping the power on is especially important for the pharmaceutical and life sciences manufacturing industry where reliable power affects everything from production to the supply chain. Determining the best path forward for your organization can be daunting and circumstances are different from company to company.

In this article, we will further define the problem, determine optimal solutions and introduce a new concept that will allow you to outsource the operation, maintenance and financing of these solutions.

Defining the Problem

Pharmaceutical and life sciences manufacturers have highly automated processes, which means they’re keenly aware of the importance of reliable power supply. It requires precise research, development, manufacturing, packaging and distribution supported by energy conversion assets (ECAs). ECAs consume energy in its raw form, converting it to an operationally intensive process.

Because these assets are often overlooked and undermaintained, deferred maintenance can be considered as an “invisible risk” – and may wreak havoc on budgets during unexpected equipment failure. This failure is costly as the site may not be able to continue some processes until the problem is resolved.

The good news? You can better protect your operations and gain efficiencies with proper maintenance and upgrades to a more reliable power system.

Considerations when determining the optimal solution for greater reliability

Design considerations for an efficient and reliable power system for your business

The pharmaceutical manufacturing industry can’t transform itself to be less reliant on power, but it can become more efficient and proactive through energy management.

Energy management can simply be described as monitoring and helping to mitigate energy consumption, use and risk. As is the case with many companies, decisions about risk are often driven by potential financial impact on the business.

Let’s explore how to make those decisions.

Define the cost of downtime

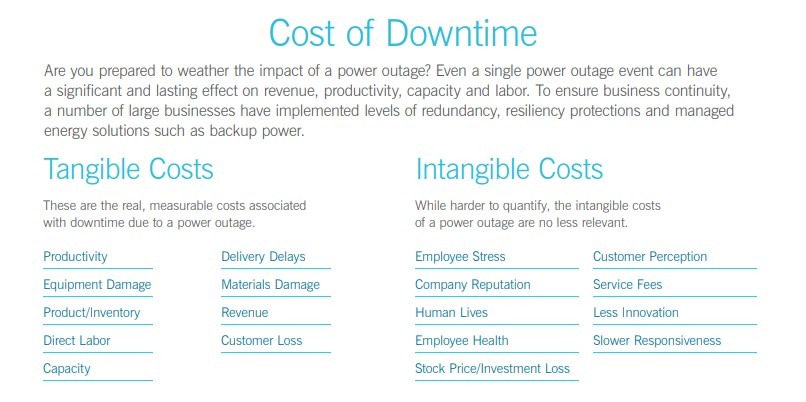

To help mitigate risks and support continuity with the right level of electricity reliability, you first need to understand the value of resiliency and the cost of power interruption. A clear understanding of this cost will identify the downside and serve as an integral factor when developing future strategies.

How would your labor, production, distribution, etc. be impacted in the event of downtime? How much would the investigation itself cost your company? Will there be a disruption to the supply chain?

These are the questions you’ll need to ask yourself to make sure you fully understand what power reliability means for your business.

Believe it or not, not all companies have a firm grip on these cost factors. Proper measurement and verification of these costs resulting from unplanned downtime or equipment failure are foundational for the analysis.

Remember to avoid comparing the cost of downtime to charges associated with a power resiliency plan. People end up making decisions based on current information rather than projected costs of owning and maintaining the equipment (i.e., think cost of lifetime ownership with a vehicle.)

It’s not an apples-to-apples comparison and can be misleading – ultimately shaping actions that aren’t beneficial to your operations or the future of your business.

(Source: Cost of Downtime)

What are your resiliency goals?

With your cost of downtime clearly defined, it’s now time to define your objectives and goals. Understanding the short- and long-term imperatives (i.e., adding equipment, growing in plant footprint, pivoting business model, etc.) will help drive better decisions.

Do you want to design a system that provides reliable power to manufacturing, research and development – or even the entire facility?

While many people think backing up the entire facility is the best option, it may not be feasible for every pharmaceutical manufacturer. As you consider your own objectives and goals – and how they relate to resiliency – it’s important to understand that competing challenges may lie in your organization. For example, the IT department may have different needs than that of your research and development, operations or testing departments.

Your checklist should start with:

-

- Operating Hours – worked, missed, scheduled

- Annual Sales

- Impact of the Event (outage) – hours of duration, recovery time

- Direct and Indirect Cost of the Outage – Labor lost during the outage and recovery, materials not produced or even lost, penalty costs if applicable, lost sales/revenue, equipment maintenance and repairs

Most companies begin with the following list of key contributing factors:

-

- Are there any business changes planned that may impact the plan?

- Do we have organizational alignment?

- Whom can we collaborate with to design, construct, operate and maintain the system?

- Is there capital available to implement or enhance our existing resiliency plan?

- Will the plan positively impact our sustainability goals?

- What is our time frame?

- Will there be business interruptions throughout development?

Once you have your goals and objectives outlined, you’re better able to create a flexible and reliable power system that best meets your organization’s needs.

Outsourcing the operation, maintenance and financing of critical power solutions.

Why pharmaceutical manufacturers turn to Energy Infrastructure as a Service

We’ve only begun to scratch the surface of how to create a flexible and reliable power system for your organization. In addition to defining the cost of downtime and site goals, you’ll also need to consider who will design the resiliency project, what type of equipment will be needed, whom to work with and how the project will impact your sustainability goals, time frame and more.

Most energy and manufacturing professionals we’ve worked with have been inundated with facts and figures about the cost of power outages. As a result, many have invested, or are planning to invest, in resiliency systems over the next 12-18 months. The manufacturing professionals we hear from are considering various technology and process solutions based on their history of outages and how these affect operations.

Standard solutions include:

-

- Microgrids

- Uninterruptible power supplies (UPS)

- Backup generators

- Solar and/or wind with battery storage

- Distributed energy systems

Sound like too much to consider? It can be for many businesses that are already juggling competing priorities. That’s why a growing number of pharmaceutical manufacturers are turning toward Energy Infrastructure as a Service (EIaaS).

EIaaS brings together all aspects of the project including design, capitalization, construction, implementation and maintenance. Doing so can help lower your risks while helping to eliminate costly recurring repairs to aging equipment.

To help you get started, a credible EIaaS provider will meet with you and your team to develop a road map toward a comprehensive solution that fits your objectives. The provider will have a source(s) available to supply the necessary capital for project implementation, and they’ll also own and be responsible for the maintenance and monitoring of the equipment. Taking ownership of the equipment means taking the risk of its operation too. This can bring a sigh of relief to many as this allows them to stay focused on their core business.

For a surprisingly small investment, organizations can pair generators and/or upgrade their solar generation and battery energy storage to include software controls to achieve a basic level of backup. These systems can potentially handle up to multi-hour outages and graceful shutdown of servers or other outage-sensitive equipment. Levels of redundancy, automation, generation and service go from there all the way through to subscription based as a service models with the lowest risk and highest electricity reliability available in the industry today.

As an added bonus, 24/7 monitoring is a crucial component of EIaaS, providing you with the peace of mind knowing your system is reliable and ready when you need it. We have helped many organizations across multiple states and industries evaluate their resiliency positions. From there, we’ve defined energy resiliency plans that consider costs of downtime and its impact on core operations and business.

Take a look at Grifols Pharmaceuticals, which was challenged to provide backup power services to 15 buildings spread across 467 acres. The site supplies life-saving plasma products that demand ultra-clean rooms and intense refrigeration requirements.

In collaboration with Duke Energy’s Energy Services, they designed a flexible centralized backup power system that supports Grifols’ sophisticated operations at lower costs than having multiple “micro-systems” spread across the campus.

Take control of your power systems

Most of the time, when we turn on a light switch or press a button, power is available for us, to which we’ve become accustomed. So, when unplanned downtime occurs, our response to the situation drives actions.

For some, the wait begins. Another option is to take action to uncover the cause, understand the ramifications to the bottom line and learn what can be done differently in the future.

Understanding your critical processes and costs associated with downtime and designing a system to help protect these aspects of your business are integral to success. Many companies are also now considering how to blend sustainability initiatives with resiliency. Renewable energy and battery storage are great options for those who are looking to reach those goals.

Choosing to work with an EIaaS provider may be the best solution for your needs. Careful selection of who you want to work with can better guide you along your energy pathway to evaluate your specific energy and resiliency needs with emerging fuel and resiliency technologies. We can’t control the weather or other events that may cause unplanned downtime, but we can be prepared for them.

If you’re ready to better protect your assets in the event of downtime, the shift to EIaaS may be easier than you think. Let’s explore solutions and options designed to help you reach your goals. Submit the contact form on our website, and a consultant will contact you to discuss your sustainability and resiliency needs. Discover more .

Duke Energy Sustainable Solutions

Duke Energy Sustainable Solutions collaborates with businesses to provide comprehensive energy infrastructure solutions for mission-critical processes to help meet the needs of our customers. Leveraging our core competencies, we invest resources, processes and capital in new and existing energy infrastructure systems to help customers reach peak performance and resiliency, based on their unique requirements.

To help mitigate risks and costs of downtime, we offer a spectrum of specialized resiliency solutions including renewable energy, backup power generation, uninterruptible power supplies (UPS), consultative assessments, distributed energy assets, advanced microgrid systems, financing and end-to-end project ownership.