Help Protect Your Manufacturing Operations with a Microgrid

North America has now deployed more microgrids than any other part of the world, and manufacturers are one of the leading adopters of the technology. As factories look to be less reliant on the power grid and integrate renewable energy into their systems, microgrids and backup power are becoming increasingly prevalent.

Today’s manufacturers face a host of challenges, which include obligations to customers, unprecedented constraints brought by the coronavirus pandemic, escalated tariffs on imported materials and goods, planning for infrastructure repairs and upgrades, maintaining a healthy workplace, and meeting sustainability goals, all while delivering on the constant expectation to lower costs across the business … year over year. In addition, every day, somewhere in the U.S. power fails due to poor weather, accidents, equipment malfunctions or other causes.

Microgrids offer a flexible platform to address several of these issues. They can help with the need for uninterrupted and resilient power, meet sustainbility goals if powered by renewable energy, control energy costs, and attract customers/investors that seek manufacturers who are responsible stewards of the environment.

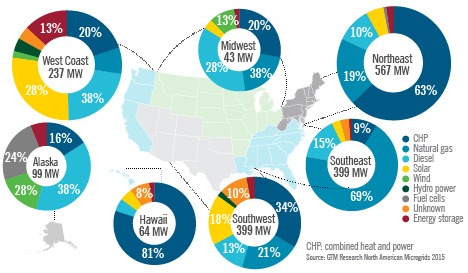

Many top U.S. companies are developing microgrids using renewable energy, conventional power sources, and smart control schemes to drive market competiveness. Microgrid deployments in the United States have continued to grow, and Microgrid KnowledgeTM and data from Navigant show “commercial and industrial (C&I) microgrids poised to grow faster than any other form of microgrid, as data centers, stores, resorts, manufacturers, and other business operations turn to the technology.”

Microgrid Deployments in the USA

The High Cost of Power Interruptions – Resilience

Robotics and automation, use of artificial intelligence (AI), and implementing 3D printing technologies are on the rise, making resilient, reliable power increasingly critical. The cost to manufacturers from power disruptions is increasing as operations are even more reliant on resilient and reliable power. Even small fluctuations in power quality can disrupt assembly lines and cause costly delays. Plastic molding, chemical processes and food production are just a few examples that can be affected during power outages. Product can be affected, and machines can jam with solidified material or be disrupted during critical temperature-sensitive reactions. These disruptions have a ripple effect beyond the factory and can even affect logistics and supply chains.

Climate Central updated an analysis of national power outage data, which shows a 67% increase in major power outages from weather-related events since 2000. Two-thirds of states (34 states and Washington, D.C.) experienced an increase in outages caused by extreme weather in recent years (source: https://medialibrary.climatecentral.org/resources/power-outages). As electricity demand rises and grids rely more on wind and solar power, where supply changes with the weather, companies will have to have increased access to backup generation.

A recent survey found that more than a quarter of manufacturing businesses experienced an outage at least once a month, with 58% reporting an outage lasting longer than an hour. For large manufacturing enterprises, a single hour of downtime can easily top the $5 million mark. A main point to analyze on the effect of a power interruption impact is to determine the true cost of downtime for your business, focusing not only on product cost and labor but also on maintenance, repairs, logistics, reassigning employees, rescheduling, etc.

Microgrid KnowledgeTM produced an example highlighting the potential costs of outages for manufacturers: Consider a car manufacturer that makes about 1,200 cars a day, and the cost for each car is roughly $50,000. Just one day offline would cost this major manufacturer $60 million.

https://bin95.com/articles/maintenance-management/whats-true-downtime-cost.htm

ESG Reporting, GHG Compliance & Reduction

ESG (environmental, social and governance) reporting is fast becoming a key indicator for major fund investors across the globe, with ESG stocks outperforming conventional ones in recent years. Many annual reports now contain sustainability statements for improvements in GHG (greenhouse gas) emissions, recycling, green energy sources, sustainable materials, operational resiliency and energy efficiency. Reducing GHG emissions may require a combination of energy efficiency projects, on-site and off-site renewable energy, and recycled raw material over all locations to achieve this goal.

Sustainable energy options in reliable microgrid energy systems have inherent components that can have significant impact on your sustainability goals. Many state and local regulations are defining aggressive EUI (energy use intensity) energy goals and have penalties within these “catalyst for change” policies that promote pressure toward carbon neutrality compliance. On-site microgrid options can mitigate some of these important issues, all while providing energy reliability for consistent plant operations.

Managing Energy Costs

Understanding today’s energy costs is paramount in manufacturing, as power is a HUGE line-item resource in the budget. Managing energy consumption and supply and being a good steward is a key driver toward improvements. Just because an organization may be large and complex doesn’t necessarily mean it is completely knowledgeable about electricity usage and managing usage across geographies. Greater dispersion equals greater energy management challenges. A microgrid can help put you in control of energy generation, usage and cost stability, and there are many options available to configure the best system for you.

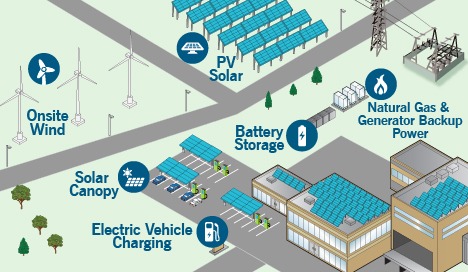

Microgrid Component Options

Some of the most well-known microgrid system components are described as follows:

1 – Roof- and Ground-mounted PV Solar Arrays

Solar PV modules can be built onto existing roofs, structures or ground-mounted frames and tied into AC inverters, batteries and other electrical infrastructure comprising a microgrid. The power generated from the panels can be channeled and stored into energy storage battery banks or incorporated with other power sources like generators and wind power via inverters that change DC to AC voltage.

When a grid outage occurs, a facility can island from the grid, using the solar generation to power operations during the day, and store excess energy in batteries to continue into nighttime.

Solar plus energy storage microgrid can provide cost savings when the grid is operating on-peak by shifting load to electricity stored during less expensive, off-peak hours.

2 – Solar Parking Canopies

Covered parking can help reduce the damage from snow, rain, sleet and heavy wind. While covered parking provides protection for the vehicle from the elements, it can also be an overlooked area for on-site renewable power generation.

3 – On-site Wind Generation

Wind generation can be coupled with battery energy storage system (BESS) to provide a robust on-site option for power generation and be an integral part of a microgrid solution and an important contributor for your sustainability goals.

4 – Battery Storage and UPS

A battery energy storage system (BESS) stores energy through battery technology. It can be deployed later to cover peak load coverage and provide microgrid stabilization. A BESS can be a critical component in the microgrid system by acting as an energy buffer when intermittent renewable electricity generation creates new demands on the grid. Main battery storage coupled with an uninterruptible power supply (UPS) system can be used to provide sensitive computer controls and data center servers with the proper stable backup voltage and protection to keep IT and control system operations online. Energy storage is not essential to a microgrid, but it is a flexible, versatile resource that can provide significant benefits. For manufacturers, the integration of energy storage in a microgrid can provide benefits by helping manage energy costs and ensure a reliable clean power supply. Besides providing increased resilience, the BESS will allow increased energy usage/cost optimization schemes to be implemented.

5 – Backup Power Generators

Conventional generator systems can provide reliable backup power during unplanned outages and may allow for participation in an emergency response program where available.

Generators can be combined with energy storage and on-site renewable energy to provide a comprehensive microgrid solution. Fuel sources can be propane, natural gas or diesel. Diesel generators have been a main backup power source for most industries. Emissions standards for generators today have stringent regulations set forth to reduce air pollutants.

6 – Fuel Cell

If your manufacturing operations have dependable access to natural gas, biogas or hydrogen, fuel cells are a great option to have in your microgrid system. Fuel cells convert these gases into electricity through an electrochemical process, and depending on the electrical load, they can provide an entire operations peak load or be a standby power source for just its critical systems. Fuel cells can supply continuous power when wind, solar, batteries or other resources are unavailable. Because of this, a fuel cell can be the energy cornerstone that the microgrid can rely on along with any other energy resources including main power from the central grid.

In addition to delivering always-on, resilient power, fuel cells reduce greenhouse gas emissions (by 50% compared to the U.S. grid) and, unlike gas combustion generators, release virtually no criteria air pollutants. They also offer a high degree of cost predictability, making it possible to lock in long-term power costs instead of facing yearly utility rate uncertainty and increases (source: www.bloomenergy.com).

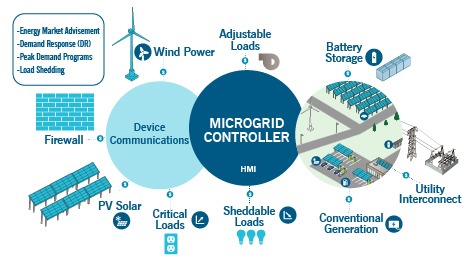

7 – Microgrid Controls and Cybersecurity

Operation of the microgrid needs to be able to change quickly under several different scenarios dependent on grid power supply, time-of-use rates, demand response (DR) agreements with the local utility, and arbitrage where a deregulated market exists for selling off excess power. A robust microgrid controls system will handle conditions in near real-time response and provide the required flexibility to accommodate dynamic optimization strategies as well as grow and change with future growth and power options.

Cybersecurity – the U.S. Department of Homeland Security ranked the manufacturing industry second highest for the most documented reports of cyberattacks. Much of this is due to increased IoT connections, which in turn increases this risk as more systems depend on the internet for updates and maintenance. It is important to incorporate microgrid controls into manufacturing cybersecurity protocols so that these critical systems are better protected from cyberattacks.

Smaller manufacturers are more likely to be targeted than their larger counterparts because cybercriminals often view them as easy entry points into larger manufacturing chains, and it has been reported by Kaspersky Labs that the average cost of a data breach for small- to medium-sized enterprises is estimated to be approximately $117,003.

Financing a Microgrid Project

We strive to minimize risks to your business, with Duke Energy One managing the design, installation, ownership, operation and maintenance of your power solutions. Duke Energy One has an innovative approach to financing, which frees capital while providing cost predictability.

“An as-a-service model can provide a project tailor-made for the end user – with less risk, and without the development and operational hassles. While many entities may have ambitions around changing how they consume their energy and reaching carbon reduction goals, the way to achieve these may be unclear or require them to take risks they may not be prepared to mitigate. By shifting those risks away from the end-user to companies built to address them, the as-a-service model enables more businesses and institutions to pursue microgrid solutions.” (source: A Look at the Year Ahead and How Microgrids Are Shaping the Power Industry (powermag.com).

Conclusion

Microgrids bring inherent benefits to many sectors of the economy. A well-designed microgrid can bring efficient and low-cost power as well as benefits to critical infrastructure where reliability and resiliency are tantamount. A well-designed microgrid with robust controls and up-to-date cybersecurity supports operational flexibility while providing predicable costs optimized not only for energy usage but also positively impacts sustainability goals. An investment in a microgrid can act as insurance for continued growth, success and innovation. A power disruption brings vulnerability and loss of time and money – a microgrid puts you back in charge.